FAQ

Whether you’re a beginner or an experienced printer, our comprehensive FAQ page is designed to address your queries and streamline your 3D printing experience. Dive into a wealth of information, tips, and troubleshooting advice to ensure your creative projects are both successful and satisfying.

Getting Started

International Shipping

3D Potter ships worldwide. If you are outside of the United States or if you don’t see a dealer in your area, please email us at: zaneta@3dpotter.com so we can get you a quote on shipping. We do not accept Purchase Orders outside of the United States.

Machine Setup and Operation

Version 10 Assembly Video: https://www.youtube.com/watch?v=zAXeDTTHlOQ

Version 10 Operation: https://www.youtube.com/watch?v=qlKjVaMu0mQ

Version 10 Files: https://drive.google.com/drive/folders/1Z75URXSYHz8LaEkh–1E-EALXg_C-xrJ

Scara Assembly Video: https://youtu.be/UsdfftpnCfE

Scara Roadrunner Assembly: https://youtu.be/vNbSFMzCWZw

Scara Operation: https://www.youtube.com/watch?v=4PYLPpY49uM

Scara Files: https://drive.google.com/drive/folders/1bgKKFmiLAjO996ld0stOVZXU9AWedp51

All other printers: https://3dpotter.com/faq-v789

Do I need 3D printer or pottery experience to use a 3D potter Printer?

You do not need previous experience, but it helps. 3D Potter ceramic printers work like standard 3D printers. 3D printers read g-code files, which must be generated by a slicing program, which then is fed a model file. If you do not have 3D printing experience, you will need to learn model file generation as well as slicing software operations. There are many videos available on YouTube that will teach you how to use 3D printers, slicing, and model generation.

Clay and its preparation is another part of using our printers. There are many factors that can affect the properties of clay and having the right consistency is key. Clay that is too hard or too soft can cause issues with our extruder system. We have YouTube videos on clay preparation. Have fun and be prepared to get dirty.

Clay preparation

1. Cut clay into smaller sections, put in microfiber towel or felt in the plastic bag, and 10-15 oz. of water, close the bag. The moisture from the cloth will penetrate into the clay in about a day or so.

2. Manual wedging with adding extra water until the consistency is right.

3. Use a pug mill and add small amounts of water while cycling the clay through the pug mill several times to get the right consistency. Then the tubes can be loaded directly from the pug mill.

Some Clay Recommendations and Observations

Clay – Laguna B-Mix 5 WC401. You can get it in prepared bags and use our preparation method.

Stoneware – Maccabees cone 5 stoneware has the best interlayer adhesion and is quite easily extruded in our extruders. We do add some water to the stoneware which seems to help with interlayer adhesion and ease of extrusion.

Earthenware – Vince’s Low White Clay earthenware performs well also although it does not extrude as easily as the stoneware. The interlayer adhesion is a little bit less than the stoneware also but this doesn’t seem to be a problem as long as you do not let the moisture come out of the clay too fast after printing.

Porcelain – Axner Mary’s Porcelain Clay is the only porcelain that we have experimented with. The interlayer adhesion seems to be a problem as the moisture dissipates too quickly on a large print. Especially on larger vessels at the overlap point after a period of time, the moisture doesn’t seem to be there. This also depends on the environment’s temperature and humidity.

There’s so much to say and so much experimenting to be done in our 3D ceramic studio. We have yet to make up our own clay preparation and this is another way to go.

Ready to Print Clay – Sio-2 has premade bagged clay, with the correct amount of water content, ready to print out of the bag. For more information please visit their website. https://www.sio-2.com/gb/content/20-3d-printing-clays-sio-2

Loading Extruder Tubes

The Pugmill

The easiest way to load extruder tubes is with a pugill. For best results, a de-airing pug mill and a double auger will give you better performance than a single auger. Although a single auger is adequate, the consistency of the clay is more critical when it comes to loading the tubes. The consistency of the clay should be similar to standard throwing clay, but wetter. This can be accomplished by running the clay through the pug mill and adding a small quantity of water. If too much water is added to the clay the pug mill can actually not function sufficiently enough to load the tubes. This happens because the auger has no traction against the side of the pug mill as the clay mixture becomes too loose. It also depends on the pug mill and its ability to forcefully push the clay. It is necessary to have an adaptor for the nozzle of the pug mill to attach the polycarbonate tube for loading.

https://www.youtube.com/watch?v=YtHcdhgxBe8

Loading by hand

Using a 25 lb. bag of prepared clay, cut the clay into 4 pieces and put a microfiber towel in between the 4 pieces. Add 15 ounces of water to the bag, close the bag and make it airtight. Wait until the water has penetrated the clay, approximately one to two days. Now using the moist clay roll it into a cylinder a little bit smaller than the inside of the tube you are loading. Put the nozzle on the tube with tape over the end and gently tap the clay into the tube. Make sure to tap the tube and nozzle on a soft surface. This is the best method to load your tubes without a pug mill.

https://www.youtube.com/watch?v=EbGbvmyD0-U

Trowel

Using a trowel or a spatula on a flat surface. Scoop clay into the tube then tap the tube on a soft surface. This will move the clay down into the tube as you continue to load the tube. If the consistency of the clay is correct, you can eliminate the air at the same time. This is the hardest loading method.

Changing tubes on the extruder

Changing out an empty tube on an extruder for a full one has many steps. Please watch our Extruder Tube Changing video for a full tutorial on how to easily change your tubes.

Software

How do I create an object?

Basic object creation and slicing tutorial: https://www.youtube.com/watch?v=umOpoPM2Asc

In order to create an object you must first develop a shape. There are some simple programs like, Tinkercad, but our favorite is Fusion 360 which is free for students and small businesses. These software programs are capable of just taking simple shapes and turning them into very attractive objects to print on our ceramic printer.

After you’ve generated your vessel, it’s a simple process with Fusion 360 or any other program to turn it into STL file. From the STL file the program needs to be sliced and processed into g-code. This process has become very simple over time with multiple free programs like Repetier, Cura, and Simplify 3D which is $150 but has some very good features and visualizations.

Once you slice your object and set the parameters for the printer, it automatically generates the G code. This G code can be saved to an SD card and inserted or uploaded into the machine.

After loading the SD card, it’s a simple process of pushing two or three buttons and your print will start. From the touchscreen you have full control over the speed and ceramic flow again so that you’re capable of fine tuning the print even while it’s in process. For our wireless design, you can view all of your files and select which file you want to print.

3D Potter recommends Cura as one of the best Slicers to be used with our printers. It is free and we provide the profile for it which imports all of the settings of our printers.

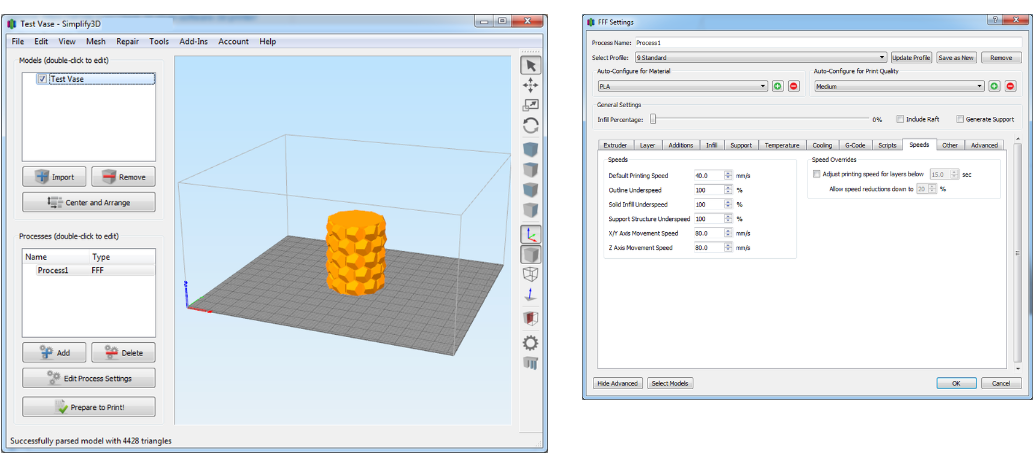

Next would be Simplify 3D, which we provide profiles for as well. You can use any slicer as long as you enter the settings.

STL File Examples

Here are some sample STL files for you to slice: https://drive.google.com/drive/folders/17zsPQ30Nu3Nb-sH_Wu8yo3gBNibHl6CU

Slicing the test files: https://www.youtube.com/watch?v=_KuHgqOmZog

It is very important that you experiment and get your slicing settings correct. Here are some tips and tricks for theses STL files. Be sure to change the object size and rotation in the slicer to fit how you want it to be.

Basic.stl- This solid core shape can be sliced with almost any setting and nozzle size. Feel free to change its dimensions or size in the slicer.

Snowflake.stl- This shell can be sliced with our settings, just like the Basic.stl file, it is quite flexible and generally slices very well.

Loops.stl- This is a more advanced object. Adding pegs sticking out creates a “loop” effect while printing. It is important to know that slicers can not print objects that are smaller than the nozzle size. One way of getting around then is using a 3mm nozzle size setting in the slicer, even if you have a 5mm or 6mm nozzle on the printer. This will cause under extrusion, so you must increase the extrusion multiplier/flow rate in the slicer, or the extrude rate in the printer interface when the print is running.

Cover Files for Version 10

Simplify 3D factory settings

These files are Simplify 3D factory setting. The real advantage with Simplify factory settings is that not only does it include the STL file, but it also includes all of the settings and parameters of the slicing program and options. So for our customers that have Simplify 3D it’s as simple as double-clicking on one of these files, Simplify 3D will automatically launch and all you have to do is generate the G-Code. All of these files have been tested on our machines here at our shop. You might have to adjust your speeds and feeds but probably only slightly for your clay consistency. If you do not use Simplify 3D, there are screen shots of the settings as well, such as printing speed in millimeters per second.

For the Scara printers, you can check the available print area with these STL files in your slicer: https://drive.google.com/drive/folders/1sh5uIvRODUoRM8zlUXEvVp5Gc3oFGE9g

Simplify 3D .FFF files (Model 7 and 8)

This is a BETA profile for our version 7 and 8 printers. Default flow rate is 500%. Flow rate may need to be adjusted +/- 100%.

Simplify 3D .FFF files (Model 9 and Scara)

9 Micro.FFF: Micro 9

9 Standard.FFF: 9, Pro 9, Super 9

9 XL.FFF: XL 9, XXL 9

SCARA 5mm 4-10.FFF: Scara Series

Simplify 3D .FFF files (Model 10)

10 Micro.FFF: Micro 10

10 PRO.FFF: 10 Pro

10 Super.FFF: 10 Super

10 XL.FFF: 10 XL- using bat placed on top

Cura settings

3D Potter now supports Cura. Download the profile for your size printer and open it with Cura, all settings will be imported. You can also install the Duet plugin and upload/print to your printer directly (not required). To install the plugin you can use the Cura marketplace or manually from the link below.

For the Scara printers, you can check the available print area with these STL files in your slicer: https://drive.google.com/drive/folders/1sh5uIvRODUoRM8zlUXEvVp5Gc3oFGE9g

Installation tutorial: https://www.youtube.com/watch?v=uZty0JzH41E (4min)

Cura Settings (Model 7 and 8) BETA Profile, Touch screen

Cura Settings (Models 9 and Sara), WiFi

3D Potter Micro.3MF: Micro 9

3D Potter Standard.3MF: 9, Pro 9, Super 9

3D Potter XL.3MF: XL 9, XXL 9

3D Potter Scara.3MF: Scara Series

Cura Settings (Model 10), WiFi

3D Potter 10 Micro.3mf: Micro 10

3D Potter 10 PRO: Pro 10

3D Potter Super 10: Super 10

3D Potter 10 XL 15in Bat: XL 10- using included bat

3D Potter 10 XL Full Range: XL 10- using bat placed on top

3D Potter 10 XL Auger 15in Bat: XL 10 Auger- using included bat

3D Potter 10 XL Auger Full Range: XL 10 Auger- using bat placed on top

3D Potter Scara

3D Potter Scara Elite Extended

(Optional) Duet plugin for Cura: https://github.com/Kriechi/Cura-DuetRRFPlugin

For the Scara printers, you can check the available print area with these STL files in your slicer: https://drive.google.com/drive/folders/1sh5uIvRODUoRM8zlUXEvVp5Gc3oFGE9g

Simplify 3D .FFF files (Model 7 and 8)

This is a BETA profile for our version 7 and 8 printers. Default flow rate is 500%. Flow rate may need to be adjusted +/- 100%.

Simplify 3D .FFF files (Model 9 and Scara)

9 Micro.FFF: Micro 9

9 Standard.FFF: 9, Pro 9, Super 9

9 XL.FFF: XL 9, XXL 9

SCARA 5mm 4-10.FFF: Scara Series

Simplify 3D .FFF files (Model 10)

10 Micro.FFF: Micro 10

10 PRO.FFF: 10 Pro

10 Super.FFF: 10 Super

10 XL.FFF: 10 XL- using bat placed on top

Printer/Slicer Settings

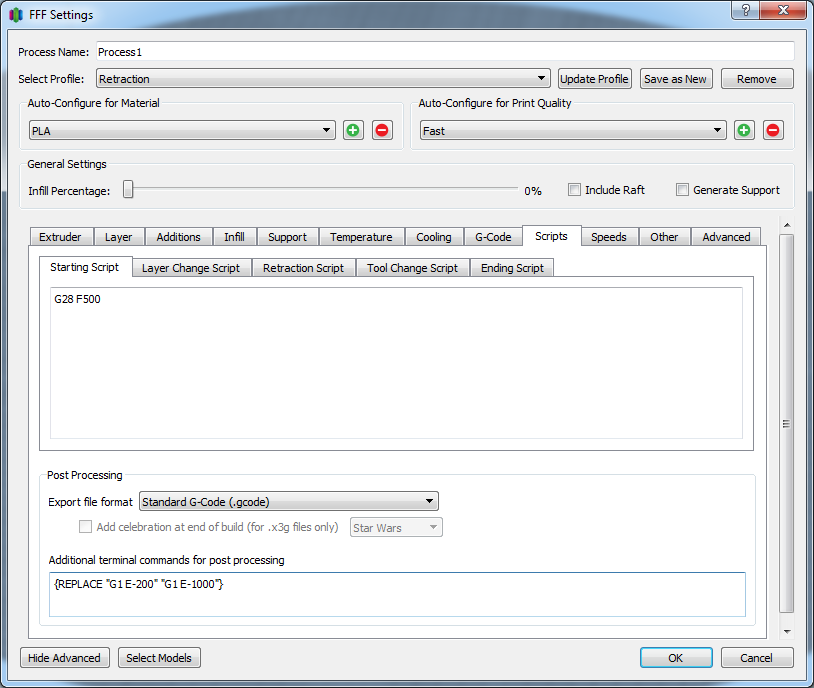

Retraction

3D Potter printers, and extruders, are fully capable of retraction in between parts of an object. This is achieved by high reverse speeds of the piston in our extruders. Below are the settings which we recommend for ideal retraction use clay.

Retraction Distance: 1000mm

Extra Restart Distance: -10mm

Retraction Vertical Lift: 5mm

Retraction Speed: 1000mm/s

Coast: 5mm

Wipe: None

You can enter these setting directly into Cura or other slicers.

Simplify 3D’s maximum retraction distance is 200mm. In the process settings window you must add a terminal command under post processing which is under the Scripts tab.

{REPLACE “G1 E-200” “G1 E-1000”}

Explanation:

We need the extruder to retract very quickly a certain amount, so we set it to retract an arbitrary distance of “1000mm.” In reality, the piston does not move up a whole meter because it has a gearbox and acme screw reduction. Right after a layer finishes in Simplfy 3D, it resets the extruder value “E” to 0. With the retraction set to -1000mm, it sends the command E-1000. Think of this as a position on a number line. After moving up 5mm and moving to the next location, it sends the command E-10. This moves it from position -1000 to -10, which reprimes the extruder. “E” is then reset to 0 again, and the next layer starts.

This is how Simplfy 3D deals with retraction, other slicing software work differently and may not need the post processing script, or may use different punctuation for scripts.

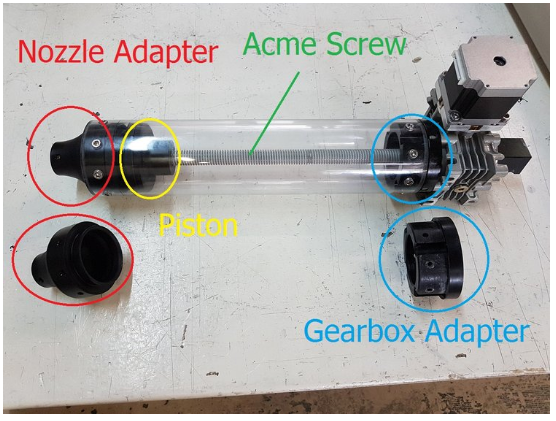

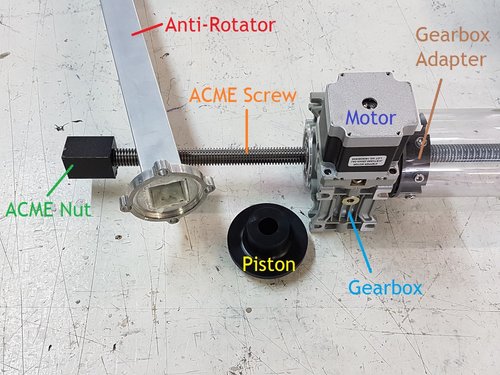

Extruder Diagram

Z Height change for version 9 and 10 printers

To change the height on version 9 and 10 printers, you only have to change the maximum Z travel distance in the config. Please watch our tutorial video for the full instructions.

https://www.youtube.com/watch?v=oyzKJ2o4D1s&t

SETTINGS THE Z TRAVEL DISTANCE BEYOND ITS MAXIMUM VALUE WILL CRASH THE MACHINE AND VOID THE WARRANTY. CRASHING THE MACHINE CAN CAUSE PERMANENT DAMAGE.

Connections

Wifi Networking

All 3D potter printers broadcast their own WiFi network to connect to. Here is a guide on basic connection: https://www.youtube.com/watch?v=5__oClYqolI

The Scara and version 9/10 printers can be connected to in multiple ways. It can connect to a WiFi network, or generate its own, thus becoming its own router. When programming the WiFi to connect to an existing network (or to generate its own), the exact name and password of the wifi network it is connecting to (or generating) must be entered as a command, this is a one time event. When it powers up it runs through all of the commands in config file located in the sys folder. One of these commands is to tell the machine to connect to a network (M552 S1) or to generate its own network (M552 S2), this must be changed to what suits your needs.

3D Potter WiFi Network Connection Guide: https://www.youtube.com/watch?v=NysPeo8uz0g

WiFi programming guide:

https://docs.google.com/document/d/1vq9BJCUo9UxAJmw9oulXlpTHEubVVADhHvjnmOfZuP8/edit

https://duet3d.dozuki.com/Wiki/Gcode#Section_M587_Add_WiFi_host_network_to_remembered_list_or_list_remembered_networks

https://duet3d.dozuki.com/Wiki/Gcode#Section_M589_Configure_access_point_parameters

Connecting to the board via USB: https://docs.duet3d.com/en/How_to_guides/Getting_connected/Getting_connected_to_your_Duet

USB drivers: https://github.com/Duet3D/RepRapFirmware/blob/dev/Driver/WindowsDriverFiles.zip

YAT terminal: https://sourceforge.net/projects/y-a-terminal/

Ethernet Networking

As an optional add-on to all of our printers, you can choose to have a non-WiFi model. This will make the printer have no WiFi module, and instead have an extra daughter board for Ethernet, perfect for facilities with WiFi restrictions.

Here is our manual on how to connect over Ethernet: https://docs.google.com/document/d/1hHrO7o_VC6m9qFqECqpWe7MxdM75YOUvm3MBIaY1gSU/edit

Lubricants

What lubricants are used with the machine?

On the main ACME screw use Lithium Grease, White. It can be purchased at most hardware stores and the Home Depot

https://youtu.be/wWvMl37TE4s?t=283

https://www.homedepot.com/p/Lucas-Oil-8-oz-Lithium-Grease-White-10533/202535870

On version 7,8,9 the printer rails have a very light coat of cleaner wax on them, make sure that not too much is applied. You should not be able too see any lumps on the rails, only a very thin sheen of reflecting light when viewed at an angle. Can be purchased at car parts stores and online.

https://www.youtube.com/watch?v=HbQcMEKAvRo

https://www.amazon.com/dp/B0002U1TVW/ref=twister_B00ODVQYE8?_encoding=UTF8&th=1

For version 10 printers use a few drops of 3-in-one oil, this lubricates the whole rail for a few months. If the rail has debris on it, be sure to remove them and then use a few drops on the cleaned section of the rail to re-lubricate it. 3-in-one is sold at most hardware stores.

https://www.youtube.com/watch?v=EhxjFMZ66GM

https://www.amazon.com/3-ONE-10038-Multi-Purpose-Pack/dp/B00065VGWK/

https://www.harborfreight.com/4-oz-multi-purpose-oil-with-marksman-spout-61495.html

https://www.walmart.com/ip/3-IN-ONE-Multi-Purpose-Oil-with-Marksman-Spout-4-OZ/26394959

Motor Settings

Linear ram extruders with robotic arms

In order to drive the linear Ram stepper motor, you will have to supply the ENGAGE, STEP, and DIRECT signals at 3 amps (these are typical stepper motor requirements).

The stepper motor we use requires ~2.7 amps so plan accordingly if you’re going to supply this directly from your equipment.

If you decide to drive your RAM remotely with hose, please be advised that we supply a hose adapter kit ($175). This kit comes with 24 inches of flexible high pressure clear hose. Please follow the recommended clay consistency when using the hose assembly. If your clay is too thick you will damage the hose assembly and/or the ram. This is a disadvantage of using a hose assembly or compressed air and auger arrangement. Your clay has to be considerately thinner in order for the pressure to remain relatively low. This is again why we recommend direct nozzle extrusion because you are able to extrude a much thicker clay and achieve much larger vessels faster and without the disadvantages of thin clay mixtures.

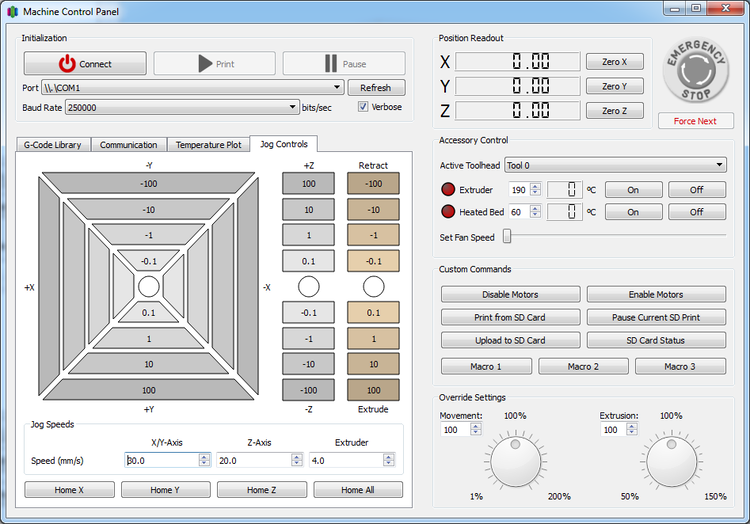

USB Control

Control Over USB Interface

Version 9, 10, and Scara Printers

You can control the printer over USB using a slicing interface such as Simplify 3D. (Other slicers may not have this functionality). Controlling a printer over USB circumvents the Duet web interface. Generally, a slicer is injecting g-code line by line in a livestream over USB when using this method. This means the slicer is in full control of the printer over USB, and the printer does not even have the file on it.

It is VERY IMPORTANT that your printer and computer are plugged into the same power source, preferably a power strip. If you have old or incorrect wiring in your building, plugging the printer into one outlet and the computer into a different one could complete a circuit once you plug in the USB cable. This will cause PERMANENT DAMAGE to your computer and the printer. This is caused by a power outlet’s ground and neutral wiring being swapped. On 120V 60Hz AC, devices still work normally if the ground and neutral wiring is swapped. However if you plug your computer into a correctly wired outlet and the printer into an incorrectly wired outlet, or vise-versa; when you connect a USB cable between them it can complete a 60v circuit which will fry them. This is not covered under our warranty.

You may need to install the Duet USB driver to use this functionality depending on what type of computer you are using. YAT is not needed for control over USB, just possibly the drivers. https://duet3d.dozuki.com/Guide/1.)+Getting+Connected+to+your+Duet/7

Troubleshooting

My extruder is making a bit of a grinding noise

The sound you are experiencing is most likely the stepper motor stalling. There are several reasons this could happen.

1. There is not enough lubrication on the screw and/or the anti-rotator nut that moves up and down the square tube (this is likely).

2. The clay is too hard, not allowing the motor to overcome to force needed to push it out through the nozzle, or there is a blockage in the nozzle (this is likely).

3. The piston is jammed in the cylinder (this is unlikely).

4. The gearbox is jammed, or the motor is defective (this is highly unlikely).

Unable to extrude the last .25" to .5" of clay in the Ram

We also get about 1/4-1/2 inch (~6-12mm) or so of harder clay remaining at the end of the clay cartridge. This can be from clay being exposed to air in the tube, causing it to dry out faster than clay in the middle of the tube. The ACME screw can also be a cause of this problem on our longer tubes. It is possible that the screw could of been bent slightly, causing a deviation from being straight the more it is extended due to clay that is too hard.

Version 7, 8 & 9

Version 7, 8, and 9 Information

Version 7 and 8 Files: https://drive.google.com/drive/u/1/folders/17SyRW33Ua2Ntg8jETBB6FJ_BKQo1oQxq

Version 9 Assembly Video: https://www.youtube.com/watch?v=2DVUnrFeb7Y

Version 9 Files: https://drive.google.com/drive/folders/1dPGVhLVZ13wzqfa5krFOvzi3MS4vp40a

Slicer Settings for version 7, 8, 9

Cura Version 7/8 (BETA): https://drive.google.com/drive/u/1/folders/1gMIT-jpuzOtrdOlDTkSo2DfiDqaj3h_L

Cura version 9: https://drive.google.com/drive/folders/1wFOqGLJi4I6vKdObJixqlId5zW_X1Xt_

Simplify 3D version 7/8: https://drive.google.com/drive/u/1/folders/17zgPP91VcT9LvdYnG0P2AAMqisem0Mls

Simplify 3D version 9: https://drive.google.com/drive/folders/1dL1q_518gyG5UT8-nL0jzhGY_x3NlxHf

Setting the Z height for additional printing room (Version 7 and 8 Printers)

When your printer arrives it’s typically set at a moderate Z height. The problem with setting maximum Z height when we ship the printer is that if you’re printing a small object it takes a long time for it to come down to the bat to start the print. If you’re always printing objects 200mm high then you should set the Z height at something like a maximum of 250mm.

If you want to utilize your 3D Potterbot to the maximum ability on the Z axis: First put a tube in the machine (with a nozzle) as high as it can go on the clamp. Now jog down the Z axis till the nozzle is almost touching the bat. Now take a tape measure and measure from the top of the car to the limit switch on the top of the Z rail (The top of the car to where it would be hitting the limit switch in its highest position). This is your maximum Z that you can enter into the configuration (Config) file in millimeters measured. DO NOT CHANGE THE FIRMWARE FILE.

https://www.youtube.com/watch?v=MKtd7GA88xM

To change this number power off the machine and unplug the power supply. Now plug that USB cable into your printer which is located under the screen. It should show up as a USB drive on your laptop. There will be two files and you want to open the config file. Look at the gamma_max (325), this is the number that you have to change to change the Z height in mm. Just hit save and that’s it. Be sure not to change this file in any other way or the machine will not function. I recommend that you back this up before you even start in case there is a problem. Do not run the USB cable while the machine is plugged into the wall.

# Endstops

endstops_enable true

scara_homing true

alpha_min_endstop 1.24^!

alpha_max_endstop nc

alpha_homing_direction home_to_min

alpha_min 0

beta_min_endstop nc

beta_max_endstop 1.26^!

beta_homing_direction home_to_max

beta_max 157.6

#gamma_min_endstop nc

#gamma_max_endstop nc

#gamma_max_travel 0

alpha_homing_retract_mm 3

beta_homing_retract_mm 3

gamma_min_endstop nc # this was working

gamma_max_endstop 1.29^! #

gamma_homing_direction home_to_max #

gamma_min 0 #

gamma_max 325 #was 325

Z Height change for version 9 and 10 printers

To change the height on version 9 and 10 printers, you only have to change the maximum Z travel distance in the config. Please watch our tutorial video for the full instructions.

https://www.youtube.com/watch?v=oyzKJ2o4D1s&t

SETTINGS THE Z TRAVEL DISTANCE BEYOND ITS MAXIMUM VALUE WILL CRASH THE MACHINE AND VOID THE WARRANTY. CRASHING THE MACHINE CAN CAUSE PERMANENT DAMAGE.

Motor Settings

Hybrid closed loop stepper motor circuit diagram: https://drive.google.com/file/d/1mM3pHgCQtC6CkLPrFC18jmNuRIZwesA1/view

3D Potter uses two type of motors on our printers, normal stepper motors and hybrid closed loop steppers. The hybrid closed loop steppers, which use green connectors, have 6 setting switches on these motors. These switches control settings such as speed and direction. If the machine is not printing correctly, such as printing ovals instead of circles or rectangles instead of squares, one of these switches my have been accidentally flipped. To change them, you need to remove to protective tape covering them, and flip them to the correct positions displayed below.

7 Series printer

X Motor 1 and 4 ON

Y Motor 1 and 4 ON

Z Motor 1 and 4 ON

Extruder Motor 3 and 4 ON

Duet Series Printer

X Motor 3 and 4 ON

Y Motor 3 and 4 ON

Z Motor 3 and 4 ON

Extruder Motor 3 and 4 ON

What lubricants are used with the machine?

On the main ACME screw use Lithium Grease, White. It can be purchased at most hardware stores and the Home Depot

https://www.homedepot.com/p/Lucas-Oil-8-oz-Lithium-Grease-White-10533/202535870

The rails have a very light coat of cleaner wax on them, make sure that not too much is applied. You should not be able too see any lumps on the rails, only a very thin sheen of reflecting light when viewed at an angle. Can be purchased at car parts stores and online.

https://www.amazon.com/dp/B0002U1TVW/ref=twister_B00ODVQYE8?_encoding=UTF8&th=1

Nozzle and Cover STL Files

3D Potter printers use PLA+ nozzles and covers. These are 3D printed parts that you can print as well. You do not need to use PLA+, you can use normal PLA, t-glass, or other 3D printer materials. We just find PLA+ to be the best material.

Nozzle Files: https://drive.google.com/drive/folders/15FejMbBkQjvuXlme5Wl7tcbEqSsKPWkT

Cover Files: https://drive.google.com/drive/folders/12SLpzrlNwbibq7HnjqErgDDbzuCozRPZ

Filament used by 3D Potter: https://www.amazon.com/eSUN-1-75mm-Printer-Filament-2-2lbs/dp/B01EKEMUEK/

Version 7/8 to 9 upgrade instructions

We have created a tutorial for those upgrading their version 7/8 printers to version 9, the tutorial is avaible in both text (w/images) and video form. The links for which are just below.

Printable Manual: https://docs.google.com/document/d/1LimjRPfLPwZ9XqfhUheBKR8Dzl_jGeTCS052M74sQ2U/edit?usp=sharing

Youtube Video Tutorial: https://www.youtube.com/watch?v=nBqA2L2S9Mg

Control Over USB

Version 7 Printers

We do not support or recommend using our printer over USB. The Smoothieware boards are not compatible with every device (Certain versions of Windows, Mac, linux, etc.) In some cases, the board is sent too much power over USB, while the machine is plugged in, causing it to draw power from two sources of electricity to run the machine. This has caused circuits to burn out..

For our printers that use the SD card and touch screen, we highly recommend that you never use the USB. The only acceptable time to use the USB is to edit the configuration file for the maximum Z rail travel distance shown in this video: https://www.youtube.com/watch?v=MKtd7GA88xM

We have had too many issues of different variations in which a whole circuit board gets fried due to issues of excess power over USB.

For information on control over USB please see: http://smoothieware.org/usb

The manufacture of the board (Smoothieware) also warns that they will not help/replace for any shorts or over voltage caused by the user.

Any damages caused by surges over USB to the machine are not covered under warranty.

Version 8, 9, 10, and Scara Printers

You can control the printer over USB using a slicing interface such as Simplify 3D. (Other slicers may not have this functionality). Controlling a printer over USB circumvents the Duet web interface. Generally, a slicer is injecting g-code line by line in a livestream over USB when using this method. This means the slicer is in full control of the printer over USB, and the printer does not even have the file on it.

It is VERY IMPORTANT that your printer and computer are plugged into the same power source, preferably a power strip. If you have old or incorrect wiring in your building, plugging the printer into one outlet and the computer into a different one could complete a circuit once you plug in the USB cable. This will cause PERMANENT DAMAGE to your computer and the printer. This is caused by a power outlet’s ground and neutral wiring being swapped. On 120V 60Hz AC, devices still work normally if the ground and neutral wiring is swapped. However if you plug your computer into a correctly wired outlet and the printer into an incorrectly wired outlet, or vise-versa; when you connect a USB cable between them it can complete a 60v circuit which will fry them. This is not covered under our warranty.

You may need to install the Duet USB driver to use this functionality depending on what type of computer you are using. YAT is not needed for control over USB, just possibly the drivers. https://duet3d.dozuki.com/Guide/1.)+Getting+Connected+to+your+Duet/7

How to re-flash the touch screen

Use a clean SD card with only the files you generate from your slicing program to prevent the firmware from being corrupted.

The touch screen has its own internal firmware separate from the control board. This firmware can be corrupted by inserting an SD card with files unfamiliar to the firmware.

I also recommend that you do not try to calibrate the screen, we have had more than a several customers attempt calibration and through miscalibration lose control of the screen. And this is another reason to reflash the firmware.

To reflash the touch screen go to this link and you’ll find one folder and 2 files. You must have the folder unzipped and named mks_pic with the files inside of it. Make sure that the 2 other files called mksconfig.txt and mkstft28.bin are not in the folder.

https://drive.google.com/drive/folders/1DBV5RblKxdkBFsivuoPm1V5pGU3L-ai0

It’s imperative that you copy these exactly like they came off the drive (all 3, the folder and two files). Load these onto a clean formatted SD card under 64 gigabytes. Insert the card and power up the machine, the files will automatically load onto the touch screen and it will be to factory new specifications. Make sure that the unzipped folder, the mks_config.txt and the mkstft28.bin are the only thing on the card when trying to reflash the firmware.

If you have problems loading programs with the SD card, there are several possible problems:

1. The SD card is a poor quality one, corrupted, or for formatted incorrectly.

2. The SD card is too large. I recommend only using small SD cards, typically I use between 1 and 4 gigabytes, even smaller cards are acceptable. We have also had problems with the high performance SD cards

3. We have also had problems with Mac computers writing additional data onto the Gcode files which make them unusable. Please be aware of this and if it’s a problem, try to switch to Windows machine.

When you flash the touch screen with these files please be aware they can only be used one time. The process of flashing the screen changes the files on the SD card. If you need to do it again, use clean card and get a fresh copy of the file from the above link.

Support

Do you offer a warranty?

Yes, a 1-year from date of purchase manufacturer defect warranty. This excludes consumable parts such as polycarbonate tubes, and ACME screws. We also will not cover damage from electrical or USB port surges, or corruption of the firmware. Full information on our warranty can be found here: 3DPotter Warranty

3D Potter's Return Policy

Latest Update Notes

Version 10 Updates

With the launch of our version 10 printers, updated system files are available for improved performance.

Upgrading from version 10.0 to version 10.1 requires removal of epoxy on parts of the printer, as well as uploading of files to the printer. Please contact our tech support department for specific instructions on how to preform this update.

Upgrading from version 10.1 to version 10.2 only requires uploading of files through the printer interface. Only the config and homing files are updated.

Version 10.1 patch notes: Improved speed on all rails. Improved interface response time. Improved homing and test files.

Version 10.2 patch notes: Fixed inverted prints from what is displayed in slicing software.

Version 10.3 patch notes: Cosmetic changes to plastic covers

You can check what version printer you are on by viewing the printer’s configuration file.

Copyright Policy

Copyright Information

All 3D potter content (on all of of our social media platforms and this website) is under a Creative Commons license. Under the Creative Commons Attribution license, commonly abbreviated as CC or CC-BY, you are free: to Share — to copy, distribute and transmit the work. to Remix — to adapt the work.

While we do not require BY to be apart of content that is Reused/Shared/Remixed, it is only our preference. BY referes to mentioning 3D Potter, giving us credit in the the content that is Reused/Shared/Remixed.