Continuous Cement Mix Station

$19,000.00

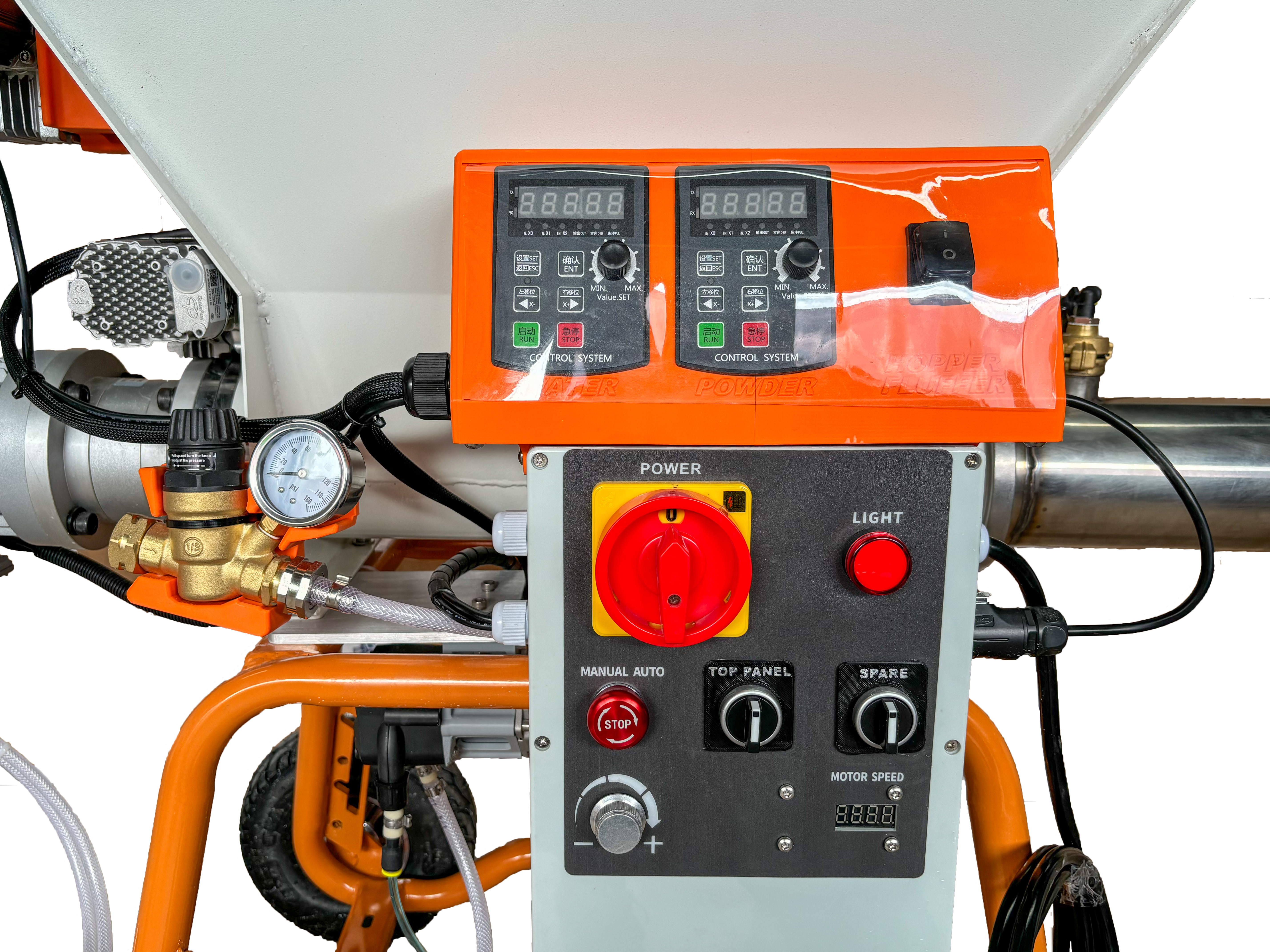

3D Potter is proud to announce the most innovative computer-controlled Mixing Station. After years of research and cooperation with Sika Corporation, the largest manufacturer of 3D printing cement, we have developed one of the most sophisticated and accurate dosing mixing machines on the market.

Please contact us to purchase this item. We only accept cash, check, or wire transfer for this item. All credit card purchases incur a 3% fee.

Continuous Cement Mix Station

This is not just another cement mixer. It is specifically constructed for the new generation of 3D printing housing structures and large objects. These materials, like Sika 733 and 752F, require more precise water dosing when mixing. It’s not possible to guess the water content during the mixing process of these new generations of materials. The manufacturer supplies exact hydration numbers, which have to be met and maintained throughout the project. Our Mixing Station constantly controls the volume of powder and also maintains the exact ratio of water. Additionally, you have full control over the mixing chamber speed and temperature during operation, and you can save your favorite presets.

We have also designed it for easy cleanup after the operation is complete. It features a preliminary self-cleaning function that evacuates most of the material before the final clean-up. The standard machine is capable of 100 lb of material within the hopper. We also offer a hopper extension (option), which doubles your capacity to approximately 200 lb of material. The hopper can accept Super Sacks from above. Super Sack support structure is supplied by other vendors. The Mixing Station is constructed with heavy-gauge powder-coated steel with aluminum reciprocating components. The motors we use are very high-quality closed-loop DC servo motors.

This truly is a game-changer when it comes to 3D printing cementitious materials.

Output Flow Rate: 6.06L per min (1.6gal per min)

Power Requirements: 220V, 20 Amp.

Water Supply: minimum 10 Psi

Compatible Machines:

- Scara Elite: Large-scale cement 3D printer – https://3dpotter.com/product/scara-elite-v2/

- Scara Elite Roadrunner: The ideal 3D printer for building houses – https://3dpotter.com/product/scara-elite-roadrunner/

- Scara HD: Purpose-built for printing large-scale projects, such as housing – https://3dpotter.com/product/scara-hd/

- Mixcell System: Designed for the injection of accelerants and coloring additives into the cementitious materials – https://3dpotter.com/product/coyote-mixcell-and-accelerant-pump/

- Mixcell HD: Designed for the injection of accelerants and coloring additives into the cementitious materials, purpose-built for large-scale construction – https://3dpotter.com/product/mixcell-hd/

- 5L Pump: Specifically designed to work with our Continuous Cement Mix Station – https://3dpotter.com/product/5l-pump-vertical-lift/

- SureFlow 40 Pump: Allows the entire printer and pump to run off a small generator or a minimal power supply – https://3dpotter.com/product/sureflow-40-pump/

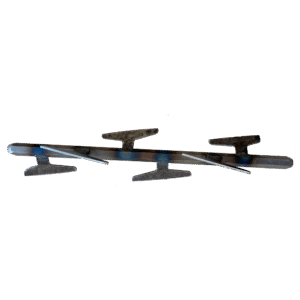

Secondary Mixer Auger

*All pumps and mixers come with a 90-day warranty.*

Warranty Policy:

https://docs.google.com/document/d/1Z9jx1DyrXjjfqQqdB9YPhhqOt0luRj0OLynrjKcb8s4/edit?usp=sharing*