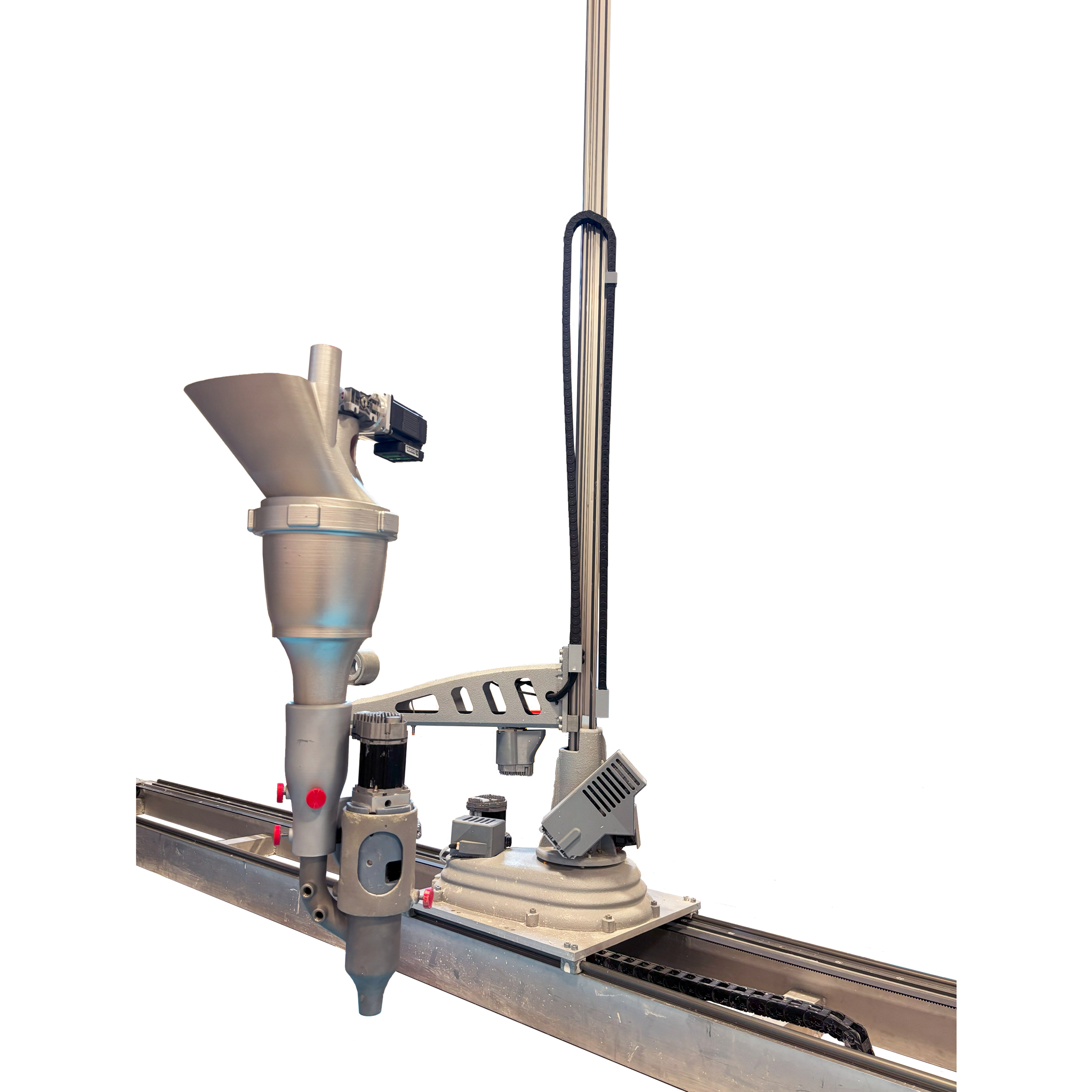

Mixcell/Auger Combo

Price range: $22,850.00 through $28,900.00

Get the Mixcell System and Auger together for a discounted price.

Please contact us if you’re interested in the Mixcell with color injection.

Get the Mixcell and Auger for a discounted price!

The Auger

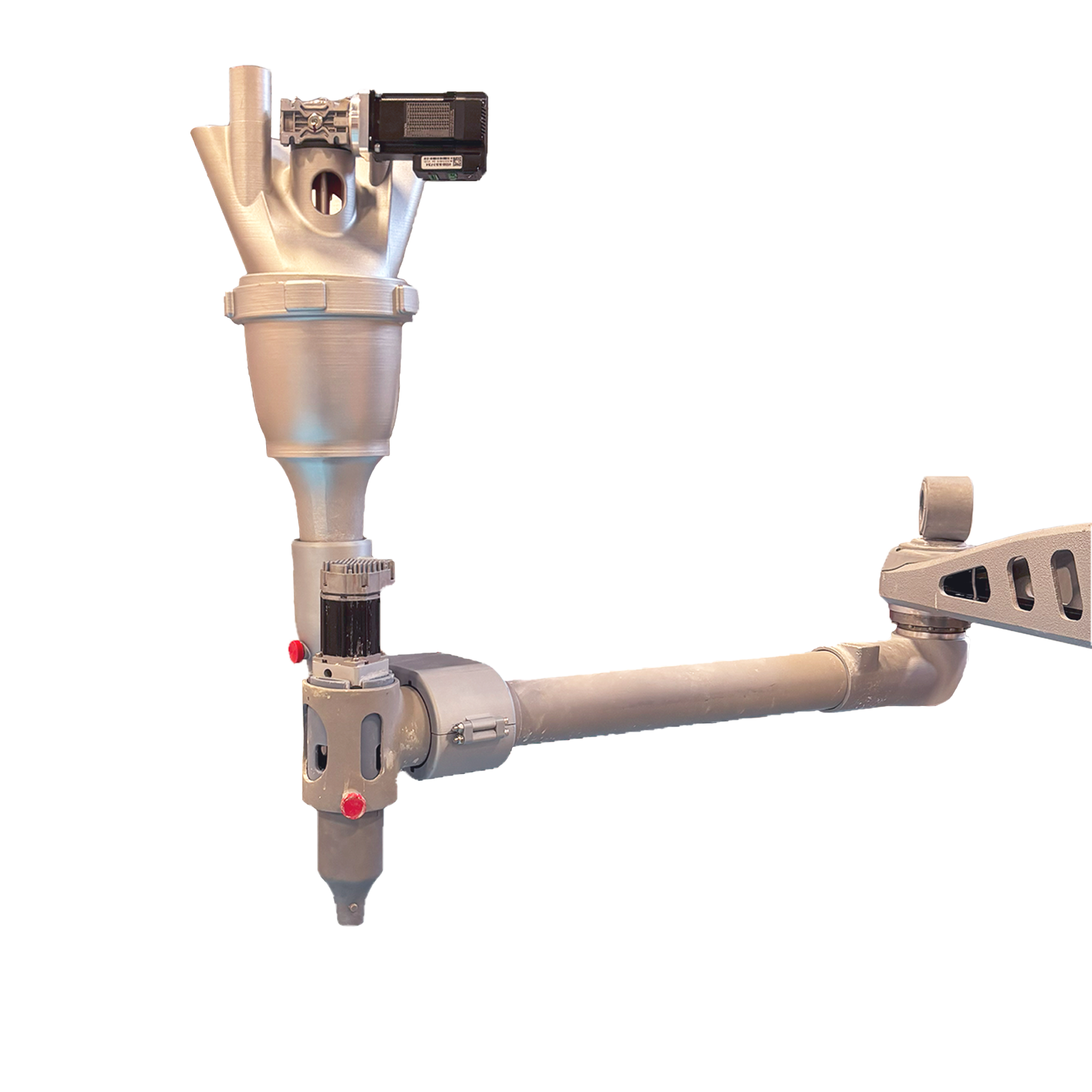

The Auger has been developed specifically for use with Cementous materials allowing you to print small-medium size objects with minimal cleanup. The easy cleanup of the auger makes it perfect for use indoor labs and material testing. The added benefit of direct flow controls means changing print speeds without having to worry about adjusting the extrusion rate. It can be fed by hand, or directly by a pump. Although this system will work with a variety of materials, there are some limitations. We recommend aggregate no larger than 2mm, and the material consistency also needs to be adjusted correctly. Avoid excessively thick materials with a high clay content.

Our Auger works especially well with the new 3D Printing products from Sika Corporation. #752

It is possible to print clay but the consistency needs to be relatively loose. With the clay at this consistency, it’s not practical to print unless you plan on injecting some other chemical to solidified clay after printing.

Weight: 12lbs (5.4kg)

Size: ~14in diameter at the top, ~28in tall.

Attachment sleeve outside diameter: ~3.5in to ~4in, 5in tall.

Stainless Steel VS Aluminum

Our aluminum auger consists of aluminum lower housing with ASA upper housing. The stainless steel version features stainless steel lower housing and aluminum upper housing.

Auger includes:

– Top drive assembly with gearbox and motor

– Auger screw assembly

– 2 nozzles, 1/2 in and 3/4 in. 1 in opening with no nozzle

– Adapter sleeve (depending on printer model it is going on)

The Mixcell System

The Mixcell is perfect for use with Sika 2K materials, such as Sikacrete-752 F 3D for both accelerant and color injection (depending on configuration). It can also be used with 1K materials like Sikacrete-733 W 3D for injecting color only. In-house testing shows material transitioning instantly after leaving the nozzle. This opens up tremendous opportunities when designing objects with overhangs that would not be possible to print without the accelerator. With the accelerator, the user can print large 8-10 ft objects nonstop with a small cross-section in addition to large structures and habitats without waiting for the material to harden. With color injection, users can simply color the concrete mixture throughout, removing the need to paint the dried concrete and reducing project completion time. The Mixcell with accelerator injection provides the opportunity to continually print a large project such as a habitat structure without stopping or waiting for the material to harden. Making unsupported overhangs when printing possible, this machine is a game-changer for cement 3D printing.

The flow rate of accelerant and color is up to 440ml per minute. The machine is able to use accelerant and color at the same time. Mixcell speed, accelerant and color are all electronically metered. An integrated high-flow water injection system allows for immediate clean up and purging of the mixing chamber after printing operation or during setup.

Mixcell Includes:

– Mixcell

– Mixcell Station

– 2 nozzles, 1/2 in and 3/4 in. 1 in opening with no nozzle

– Accelerant pump

– Coloring Pump (if purchased)

Compatible Machines and Accessories:

- Scara Elite: Large-scale cement 3D printer – https://3dpotter.com/product/scara-elite-v2/

- Scara Elite Roadrunner: The ideal 3D printer for building houses – https://3dpotter.com/product/scara-elite-roadrunner/

*All pumps and mixers come with a 90-day warranty.*

Warranty Policy:

https://docs.google.com/document/d/1Z9jx1DyrXjjfqQqdB9YPhhqOt0luRj0OLynrjKcb8s4/edit?usp=sharing*